Since 2002

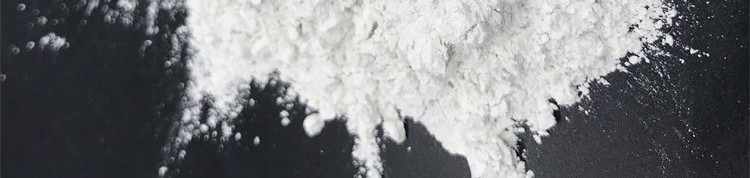

HPM® GFM-50

Glass Fiber Micro Powder

Enhance Concrete Durability and Strength

Since 2002, we have specialized in concrete crack resistance, waterproofing, and anti-corrosion technologies.

Ultrafine Reinforcing Glass Fiber Micro Powder | PIONEER®

Enhance Concrete Durability and Strength with Glass Fiber Powder

Improve your concrete and mortar performance with PIONEER® glass fiber micro powder engineered for crack resistance, toughness, and superior microstructure refinement.

What Is PIONEER® Glass Fiber Micro Powder for Cementitious Reinforcement?

PIONEER® HPM® GFM-50 is an ultrafine reinforcing glass fiber micro powder developed for concrete, mortar, UHPC, and cement-based composites. With particle sizes below 10 μm and high surface area, this alkali-free E-glass fiber powder refines microstructure, enhances toughness, reduces microcracking, and improves long-term durability in advanced concrete systems while maintaining easy dispersion in dry and wet processes.

Technical Specifications of Glass Fiber Micro Powder for Concrete and Mortar

Explore the consistent, high-purity properties of PIONEER® glass fiber powder for enhancing cementitious materials:

-

Material: Alkali-free E-glass fiber

-

Type: Ultrafine micro powder

-

Average Particle Size: <10 μm

-

Specific Gravity: 2.6 g/cm³

-

Purity: >99% glass fiber

-

Bulk Density: 0.3–0.5 g/cm³

-

pH (in water): 7–9

-

Moisture Content: <0.5%

-

Color: White

Standards Compliance for Glass Fiber Powder Cement Reinforcement

PIONEER® glass fiber micro powder aligns with international standards to ensure reliable performance:

-

ASTM C1240: Mineral admixtures for concrete

-

EN 13263: Silica fume and mineral admixtures

How Glass Fiber Micro Powder Strengthens Concrete?

Learn how PIONEER® glass fiber micro powder enhances concrete microstructure, increases strength, and improves crack resistance.

The ultrafine particles fill micro-voids, reduce porosity, and refine the interfacial transition zone between aggregates and cement paste. This leads to improved compressive and flexural strength, enhanced bonding, reduced permeability, and increased resistance to cracking, making it ideal for high-performance concrete, UHPC, mortars, and repair materials.

.jpg)

Fiberglass resin composite materials

Fiberglass grating grid plate

Key Benefits of Using Glass Fiber Micro Powder in Concrete

Maximize performance in your projects with PIONEER® glass fiber micro powder:

-

Refines microstructure, reducing porosity

-

Enhances crack resistance and toughness

-

Improves compressive and flexural strength

-

Promotes better bonding between cement paste and aggregates

-

Reduces permeability, increasing durability

-

Easy to disperse in dry and wet mixing

-

Compatible with various concrete and mortar formulations

Applications of Glass Fiber Micro Powder for Cementitious Reinforcement

PIONEER® glass fiber powder is used globally in:

-

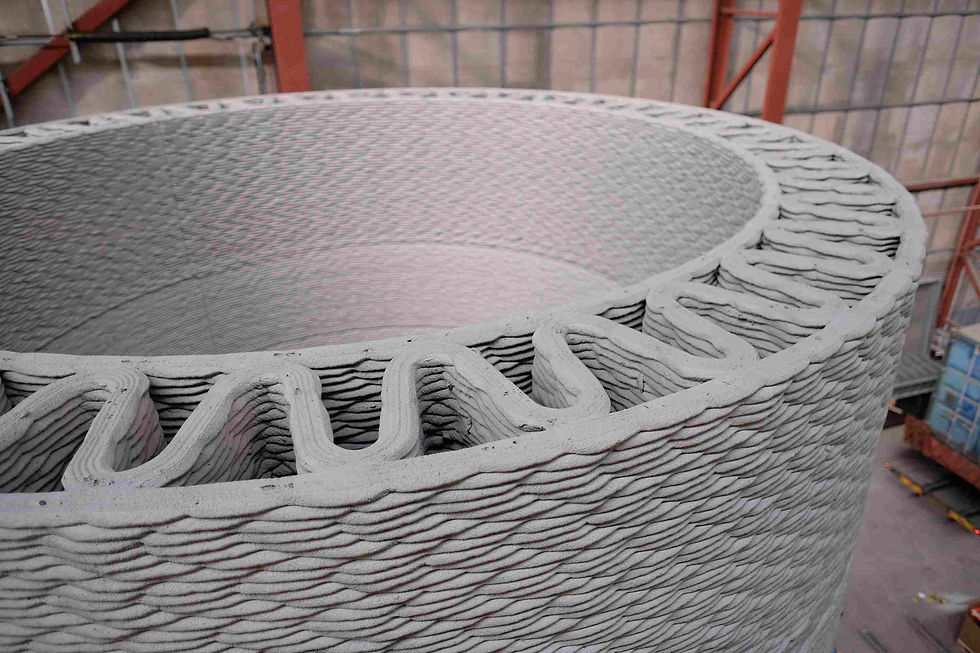

High-performance concrete and UHPC

-

Mortars and overlays for repair and protection

-

Cement-based composites and fiber-reinforced products

-

Grouts and specialty cementitious materials

-

Decorative and architectural concrete elements

Precast elements

3D-printed construction materials

Aerospace composite materials

How to Use Glass Fiber Micro Powder in Concrete?

Ensure optimal use of PIONEER® glass fiber micro powder in your production:

1. Dosage: Typically 0.5–2% by weight of cementitious materials

2. Mixing: Add gradually during dry or wet mixing for even distribution

3. Handling: Use PPE and dust control during handling

4. Storage: Store in sealed, moisture-protected packaging

Custom Glass Fiber Micro Powder Solutions for Your Projects

PIONEER® offers flexibility to meet your project requirements:

-

Customizable particle size distributions for specific needs

-

Packaging options: bulk bags, moisture-protected sacks, small packs

-

Technical support for mix design optimization and performance guidance

Why Choose PIONEER® as Your Concrete Fiber Supplier

Partner with a direct manufacturer with over 22 years of expertise in synthetic fiber reinforcement for concrete and mortar.

22 Years of Expertise in Fiber Reinforcement

PIONEER® provides consistent, high-performance fibers that ensure long-term success in concrete slabs, precast elements, industrial floors, and critical infrastructure projects, making us a trusted supplier in the global market.

1,000+ Projects in 20+ Countries

Our fibers are applied in major projects, including the Hong Kong-Zhuhai-Macao Bridge, Bangladesh Subsea Tunnel, Walmart Superstores, and metro systems, demonstrating our proven capability in fiber-reinforced concrete and mortar applications.

Direct Manufacturer, One-Stop Service

We provide complete technical support, including dosage optimization, mix design consultation, and on-site application guidance to ensure your projects succeed with fiber-reinforced concrete and mortar.

PIONEER® Headquarters

26,500m² production base

Advanced fiber dispersibility

Exceptional tensile strength

Why Choose Us?

Proven Expertise & Greater Savings

22 years of focus

on concrete protection solutions.

20+ patents & awards

In concrete durability technology

20+ countries served

with global product distribution.

1,000 projects proven

in diverse applications worldwide.

Looking for a Quote or More Information about Our Fibers?

At PIONEER, we’re committed to delivering the best and most relevant information to support your needs. Reach out to us for more details and discover the benefits we offer:

-

Factory-Direct Pricing

-

Expert Guidance on Fiber Applications

-

Customized Solutions for Your Project

-

Fiber Samples Available for Testing

Privacy Assurance: We respect your privacy and will never share your information.

Contact Us

For product inquiries, OEM/ODM partnerships, or becoming a distributor: Sales@pioneerfibre.com

For technical support and application guidance: Support@pioneerfibre.com

Regional WhatsApp Contacts

We typically respond within 24 hours, ensuring your project continues without delays.

-

Global Sales Director: +1 (929) 569-9989

-

Global Technical Director: +1 (929) 569-9992

-

Americas: +1 (702) 307-8327

-

Europe: +86 15162405106

-

Australia & South Asia: +1 (949) 317-7180

-

Southeast Asia: +86 19015435408

-

Middle East & Africa: +1 (971) 369-8821

.jpg)