Since 2002

Since 2002

HPM® EG-T

E-Glass Fibers for Thermoplastics

Lightweight, High-Strength Fiberglass Reinforcement

Since 2002, we have specialized in concrete crack resistance, waterproofing, and anti-corrosion technologies.

E-Glass Chopped Strands for Thermoplastics | PIONEER®

Lightweight, High-Strength Fiberglass Reinforcement for Thermoplastics

Upgrade your thermoplastic composites with PIONEER® E-glass chopped strands engineered for consistent dispersion, high mechanical performance, and efficient processing in extrusion and injection molding.

What Are PIONEER® HPM® E-Glass Chopped Strands for Thermoplastics?

Unlock stronger, lightweight, and durable thermoplastic parts with PIONEER® HPM® EG-T, a high-performance E-glass chopped strand specifically designed for thermoplastic compounding and injection molding. Made from alkali-free fiberglass, these soft chopped strands enhance tensile, flexural, and impact strength while maintaining smooth melt flow and stable processing, ensuring consistent results for automotive, electrical, and industrial composite applications.

Technical Specifications of Our Fiberglass Fibers for Thermoplastic Reinforcement

Explore the reliable properties that ensure stable, high-strength thermoplastic compounding.

-

Material: Alkali-free E-glass (fiberglass)

-

Type: Soft chopped strands

-

Specific Gravity: 2.6 g/cm³

-

Filament Diameter: 13 µm

-

Lengths: 3 mm, 4.5 mm, 6 mm (customizable)

-

Moisture Content: <0.05%

-

Loss on Ignition: 0.55 ± 0.15%

-

Sizing: Compatible with PP, PA, PBT, ABS, and more

-

Color: White

International Standards for Thermoplastic Fiberglass Fibers

PIONEER® EG-T fibers comply with key international standards, ensuring quality and consistency.

-

ISO 1887: Loss on ignition of glass fiber

-

ISO 3344: Moisture content determination

-

ISO 2559: Specification for textile glass fabrics

How Fiberglass Fibers Strengthen Thermoplastic Composites

Discover how PIONEER® fiberglass fibers improve your thermoplastic products’ performance while maintaining lightweight efficiency.

HPM® EG-T fiberglass chopped strands disperse evenly during compounding and molding, forming a reinforcing network that significantly improves tensile, flexural, and impact strength. The fibers allow smooth extrusion and injection molding, supporting stable processing while enhancing the structural integrity of automotive, electrical, and industrial thermoplastic components.

Industrial applications – pump components

Automotive components – bumpers

Key Benefits of Using Fiberglass Fibers in Thermoplastics

Leverage high-strength fiberglass reinforcement to improve the performance and durability of thermoplastic composites.

-

High Mechanical Strength: Enhances tensile, flexural, and impact resistance.

-

Excellent Dispersion: Fast, uniform distribution without clumping.

-

Smooth Processing: Supports stable melt flow in extrusion and molding.

-

Chemical Resistance: Withstands harsh environments and corrosion.

-

Lightweight Reinforcement: Strengthens without excessive weight.

-

Versatile Compatibility: Suitable for various resin systems.

Applications of Fiberglass Chopped Strands in Thermoplastics

Adaptable across industries, PIONEER® fiberglass fibers optimize thermoplastic reinforcement for durable, lightweight solutions.

-

Automotive: Bumpers, under-hood parts, panels

-

Electrical: Connectors, housings, insulation

-

Consumer Goods: Appliance housings, sports equipment

-

Construction: Panels, profiles, GRC components

-

Industrial: Pump housings, reinforced components

Sports equipment

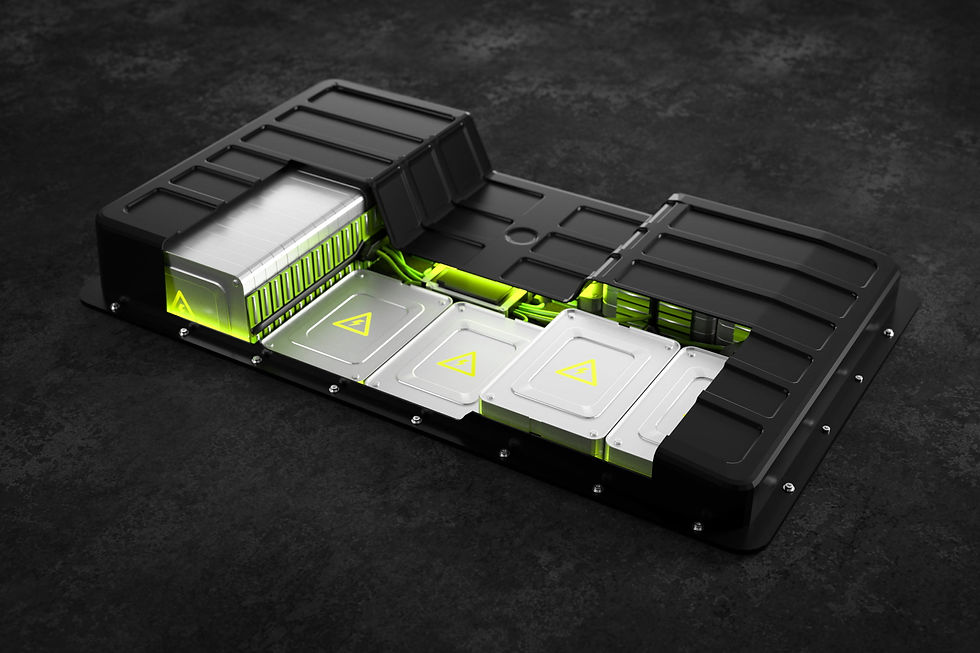

Battery housings

Connectors

How to Use E-Glass Chopped Strands for Thermoplastic Reinforcement

Ensure seamless integration into your production processes for maximum performance.

-

Dosage: 20–40 wt% depending on property requirements

-

Length Selection: 3 mm for high-flow; 4.5–6 mm for higher strength

-

Mixing: Add gradually during extrusion or compounding for even dispersion

-

Processing: Maintain optimal melt conditions for complete wet-out

Custom Fiberglass Fiber Solutions for Thermoplastic Projects

We tailor lengths, sizing, and packaging to match your thermoplastic fiberglass compounding needs.

Lengths:

-

3 mm, 4.5 mm, 6 mm, or customized

Packaging:

-

Ton bags, large paper bags, or 5–25 kg cartons

OEM/ODM:

-

Available for distributors and private label projects

Why Choose PIONEER® as Your Concrete Fiber Supplier

Partner with a direct manufacturer with over 22 years of expertise in synthetic fiber reinforcement for concrete and mortar.

22 Years of Expertise in Fiber Reinforcement

PIONEER® provides consistent, high-performance fibers that ensure long-term success in concrete slabs, precast elements, industrial floors, and critical infrastructure projects, making us a trusted supplier in the global market.

1,000+ Projects in 20+ Countries

Our fibers are applied in major projects, including the Hong Kong-Zhuhai-Macao Bridge, Bangladesh Subsea Tunnel, Walmart Superstores, and metro systems, demonstrating our proven capability in fiber-reinforced concrete and mortar applications.

Direct Manufacturer, One-Stop Service

We provide complete technical support, including dosage optimization, mix design consultation, and on-site application guidance to ensure your projects succeed with fiber-reinforced concrete and mortar.

PIONEER® Headquarters

26,500m² production base

Advanced fiber dispersibility

Exceptional tensile strength

Why Choose Us?

Proven Expertise & Greater Savings

22 years of focus

on concrete protection solutions.

20+ patents & awards

In concrete durability technology

20+ countries served

with global product distribution.

1,000 projects proven

in diverse applications worldwide.

Looking for a Quote or More Information about Our Fibers?

At PIONEER, we’re committed to delivering the best and most relevant information to support your needs. Reach out to us for more details and discover the benefits we offer:

-

Factory-Direct Pricing

-

Expert Guidance on Fiber Applications

-

Customized Solutions for Your Project

-

Fiber Samples Available for Testing

Privacy Assurance: We respect your privacy and will never share your information.

Contact Us

For product inquiries, OEM/ODM partnerships, or becoming a distributor: Sales@pioneerfibre.com

For technical support and application guidance: Support@pioneerfibre.com

Regional WhatsApp Contacts

We typically respond within 24 hours, ensuring your project continues without delays.

-

Global Sales Director: +1 (929) 569-9989

-

Global Technical Director: +1 (929) 569-9992

-

Americas: +1 (702) 307-8327

-

Europe: +86 15162405106

-

Australia & South Asia: +1 (949) 317-7180

-

Southeast Asia: +86 19015435408

-

Middle East & Africa: +1 (971) 369-8821