Basalt vs Polypropylene: Which Fiber Enhances Concrete Toughness Better?

- pioneerfiber

- Aug 25, 2025

- 2 min read

Updated: Jan 15

Information Tags

• Type: 4-minute read

• Audience: Construction professionals, engineers, architects, contractors

Need technical support or material recommendations?

Email us at solutions@pioneerfibre.com or WhatsApp +1 (949) 317-7180.

Introduction

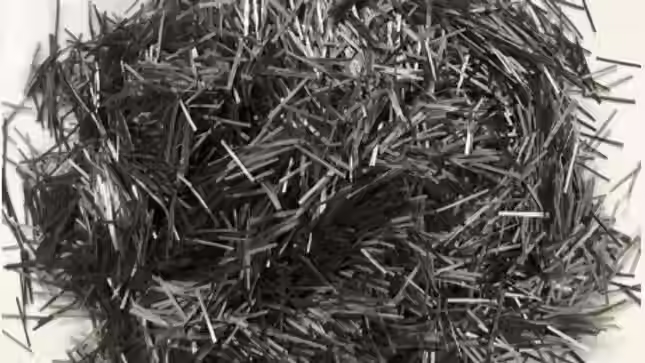

In the world of fiber-reinforced concrete, two major players dominate the discussion: basalt fibers and polypropylene fibers. Both serve to improve crack resistance and structural performance, but when it comes to concrete toughness, the choice between basalt vs polypropylene becomes critical. Understanding the mechanical properties, durability, and application scenarios of these fibers helps engineers and contractors select the right reinforcement for long-term success.

Basalt vs Polypropylene: Which Fiber Enhances Concrete Toughness Better?

To evaluate basalt vs polypropylene in terms of concrete toughness, we must first understand the key performance indicators that define toughness:

Property | Basalt Fiber | Polypropylene Fiber |

Tensile Strength | Up to 3000 MPa | Typically 400–600 MPa |

Elastic Modulus | 86–90 GPa (high modulus) | ~3–5 GPa (low modulus) |

Thermal Resistance | Excellent, > 800°C | Melts around 160°C |

Chemical Stability | Alkali, acid, salt resistant | Good, but can degrade under UV or chemical exposure |

Bond with Cement | Mineral compatibility | Relatively weak, smooth surface |

Impact on Toughness | Structural contribution | Plastic deformation, not load-bearing |

Basalt fibers, with their high modulus and mineral composition, contribute directly to structural toughness, improving post-crack energy absorption and impact resistance. Polypropylene fibers mainly control early-age plastic shrinkage cracks but provide limited support under mechanical loading.

Real-World Applications Favoring Basalt Toughness

While polypropylene fibers are widely used in general-purpose concrete for plastic shrinkage crack control, basalt fibers shine in structural and demanding environments:

Precast Elements: Basalt ensures dimensional stability and impact resistance in thin-walled components.

Shotcrete for Mining and Tunneling: Superior post-crack toughness under dynamic loads.

Industrial Flooring: Withstands thermal cycling, heavy impact, and abrasion.

Bridge Decks & Infrastructure: Provides resistance to freeze-thaw and chloride-induced corrosion.

Asphalt Reinforcement: Higher thermal stability than polypropylene, extending pavement life.

Contractors increasingly choose basalt for high-performance concrete (HPC) and ultra-high-performance concrete (UHPC) to meet modern structural standards.

Why Basalt Excels in Enhancing Concrete Toughness

Several technical factors give basalt fibers a distinct advantage:

Higher Modulus = Faster Stress Response: Early engagement with developing microcracks.

Mineral Bond = Stronger Cement Adhesion: Prevents slippage and debonding under load.

Thermal & Chemical Stability: Maintains integrity in extreme conditions where polypropylene may degrade.

Long-Term Performance: Minimizes the need for repairs or reinforcement over time.

By contrast, polypropylene acts more like a crack mitigator than a structural contributor.

Conclusion: Choosing the Right Fiber for Long-Term Toughness

When it comes to concrete toughness, the basalt vs polypropylene comparison clearly favors basalt in structural and high-performance applications. While polypropylene has its place for controlling plastic shrinkage, basalt delivers genuine reinforcement—enhancing both crack resistance and mechanical strength for demanding construction environments.

For contractors and engineers aiming for resilient, long-lasting concrete, PIONEER® HPM® Basalt provides a future-proof solution.

Explore PIONEER’s range of concrete reinforcement fibers and how they improve concrete properties. Visit our website: www.pioneerfibre.com

Micro fiber >> Learn More

Macro fiber >> Learn More

Steel fiber >> Learn More

Asphalt fiber >> Learn More

Looking for a tailored fiber or concrete reinforcement solution?

📧 Email: solutions@pioneerfibre.com

📱 WhatsApp: +1 (949) 317-7180

Our technical team supports mix design optimization, material selection,and project-specific recommendations worldwide.

Comments