What Are Micro Synthetic Fibers? A Complete Beginner’s Guide

- ppmagic2121

- Nov 18, 2025

- 3 min read

Updated: Nov 29, 2025

Suitable for architectural engineers, structural engineers, flooring contractors, precast component manufacturers, and technicians.

What Are Micro Synthetic Fibers?

Micro synthetic fibers are extremely fine synthetic filaments added to concrete, mortar, and plaster to reduce plastic shrinkage cracking, improve durability, and enhance early-age performance. They form a uniform three-dimensional reinforcement network within the cement matrix, providing measurable benefits during the fresh and hardened stages of concrete.

This beginner’s guide explains what micro synthetic fibers are, how they are manufactured, why they are used in concrete, where they are applied, and how they compare with other reinforcement materials.

Definition of Micro Synthetic Fibers

Micro synthetic fibers are man-made polymer fibers with very small diameters, typically added to concrete in low dosages to control early-age cracking and improve the material’s cohesion.

What Qualifies as “Micro” (Diameter & Length)

Micro synthetic fibers usually fall within the following ranges:

Diameter: 10–40 microns (0.01–0.04 mm)

Length: 3–19 mm (most commonly 6 mm, 12 mm, 19 mm)

Aspect ratio: 200–600

Their very small diameter allows them to interact with micro-cracks before they become visible, making them extremely effective for plastic shrinkage crack control.

Typical Materials (PP / PET / PVA)

Micro synthetic fibers are generally made from:

PP (Polypropylene) → most common, hydrophobic, versatile

PET (Polyester) → higher modulus, good for mortar/plaster

PVA (Polyvinyl Alcohol) → excellent bond, often used in UHPC

These materials are chemically stable and non-corrosive, making them ideal for concrete reinforcement.

How Micro Synthetic Fibers Are Made

Micro synthetic fibers are produced through controlled manufacturing processes designed for uniformity, strength, and consistent performance.

Raw Materials

Production begins with:

Virgin polypropylene pellets

Polyester chips

PVA resin

Stabilizers and additives (if required)

These raw materials determine the fiber’s strength, elasticity, and chemical resistance.

Extrusion & Cutting Process

The typical manufacturing steps include:

Melting & extrusion → heated polymer is extruded into continuous filaments

Stretching (orientation) → improves tensile strength and modulus

Cooling & stabilization

Precision cutting into micro-length fibers:

6 mm

12 mm

19 mm

The final product is a uniform, free-flowing micro synthetic fiber ready to be dispersed in concrete.

Why Micro Synthetic Fibers Are Added to Concrete

Micro synthetic fibers serve as a non-structural reinforcement system designed mainly for early-age crack control and improved surface performance.

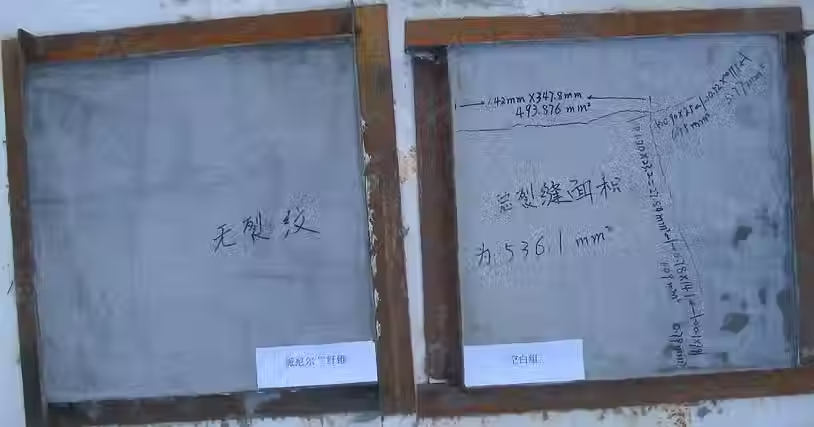

Plastic Shrinkage Crack Reduction

Plastic shrinkage cracks form in the first few hours after placement due to rapid moisture loss.Micro synthetic fibers:

Bridge micro-cracks at the earliest stage

Reduce evaporation-induced stresses

Minimize crack width and crack area

Maintain cohesion and stability during the plastic phase

Temperature & Drying Shrinkage Control

Micro fibers help buffer internal stresses caused by:

Temperature gradients

Cement hydration heat

Early-age shrinkage

Settlement

They distribute stress throughout the matrix, reducing cracking risk.

Benefits of Using Micro Synthetic Fibers

Crack Control

Micro fibers significantly reduce:

Plastic shrinkage cracking

Settlement cracking

Early-age temperature cracking

Surface Durability

Concrete with micro synthetic fibers demonstrates:

Improved abrasion resistance

Reduced permeability

Better resistance to freeze–thaw cycles

More uniform surface hardness

Finish Improvements

Because micro fibers are extremely fine:

They remain invisible after finishing

They do not interfere with troweling

They enhance cohesion for cleaner edges and surfaces

Common Applications

Micro synthetic fibers are widely used across commercial, industrial, and infrastructure projects.

Industrial Floors

Fibers help prevent early-age cracking caused by large slab areas, rapid drying, and surface finishing operations.

Precast Concrete

Micro fibers improve:

Green strength

Handling durability

Mold release quality

Edge sharpness

Shotcrete

In sprayed concrete, micro fibers reduce rebound, improve adhesion, and enhance resistance to thermal cracking.

Comparison with Other Reinforcement Materials

Micro Fibers vs Macro Fibers

Micro Synthetic Fibers | Macro Synthetic Fibers |

Control plastic shrinkage | Provide post-crack load capacity |

6–19 mm length | 40–60 mm length |

Non-structural | Structural |

Used at low dosages | Higher dosages |

Improve surface quality | Replace light steel mesh |

Micro Fibers vs Wire Mesh

Micro fibers:

Provide uniform distribution throughout the matrix

Control cracks before they form

Cannot rust

Do not require installation labor

Wire mesh:

Controls cracks after they occur

Requires placement, support chairs, and labor

Can corrode

Often misplaced or ineffective in slabs

Learn more about HPM® PP polypropylene microfiber

See all micro synthetic fiber types

Compare with macro synthetic fibers

Comments