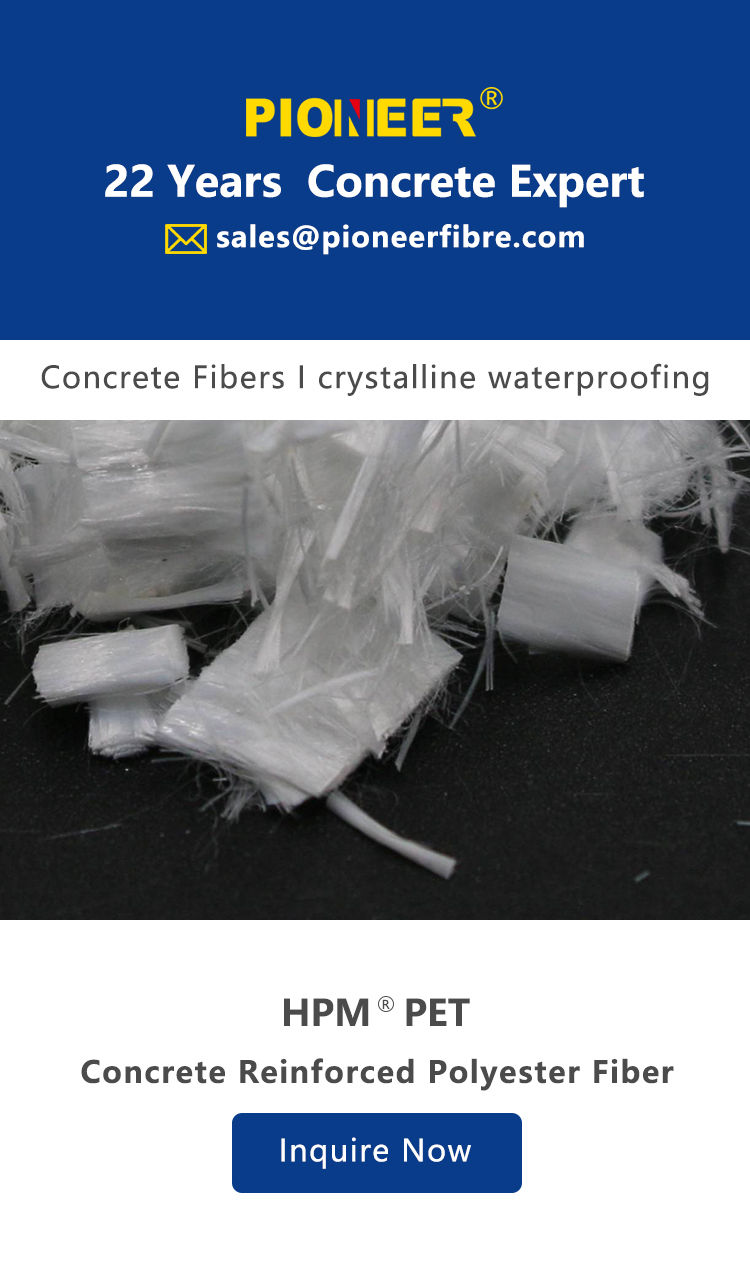

HPM® PET

Polyester Fiber for FRC

Designed for concrete and dry mortar

Since 2002, we have specialized in concrete crack resistance, waterproofing, and anti-corrosion technologies.

Polyester Fiber for Fiber-Reinforced Concrete | PIONEER®

Durable, High-Tensile Micro Synthetic Fiber for Crack Control & Concrete Longevity

Upgrade your concrete and mortar performance with PIONEER® HPM® PET, a high-tenacity polyester microfiber designed to strengthen cementitious materials, reduce plastic shrinkage cracking, and improve long-term durability across industrial, precast, flooring, and infrastructure applications.

What Are PIONEER® HPM® PET Polyester Fibers?

PIONEER® HPM® PET is a high-performance monofilament polyester fiber optimized for fiber-reinforced concrete (FRC) and dry-mix mortar systems.

The fibers disperse uniformly during mixing to form a three-dimensional micro-reinforcement network, delivering:

-

Higher tensile strength & flexural toughness

-

Controlled plastic shrinkage & drying shrinkage

-

Improved resistance to impact, abrasion, and crack propagation

-

Enhanced surface quality without visible fiber exposure

Ideal for slabs, industrial floors, precast concrete, shotcrete, asphalt concrete, and repair mortars.

Technical Specifications of Our Polyester Fibers

Optimized for consistent reinforcement in concrete & mortar:

-

Material: 100% modified polyester (PET)

-

Fiber Type: Monofilament micro synthetic fiber

-

Diameter: 0.02 mm

-

Available Lengths: 6 mm / 12 mm / 19 mm

-

Tensile Strength: 600 MPa (high tensile)

-

Elastic Modulus: 7 GPa

-

Chemical Resistance: Excellent resistance to alkalis, acids & environmental exposure

-

Color: White

How Polyester Fibers Improve Concrete Durability?

When blended into concrete or mortar, HPM® PET fibers:

-

Create a reinforced microstructure that increases tensile strength

-

Reduce plastic shrinkage cracking, the main cause of early-age failure

-

Minimize drying shrinkage, limiting long-term crack formation

-

Improve flexural performance and impact resistance

-

Support smooth troweling and high-quality finishing

-

Remain invisible in architectural or decorative concrete applications

Suitable for: slabs, floors, pavements, precast elements, shotcrete, overlays, and high-performance repair mortars.

Reduce cracking in dry-mix mortar applications

Introduce fibers into the concrete mix

Key Benefits of Using Polyester Fibers in FRC

-

Superior crack control for plastic & drying shrinkage

-

Enhanced durability with increased toughness & abrasion resistance

-

Consistent dispersion, ensuring uniform reinforcement

-

Smooth finishing, ideal for industrial and decorative concrete

-

Excellent chemical & environmental resistance, extending service life

-

Cost-effective, compatible with standard concrete mix designs

International Standards Compliance

PIONEER® HPM® PET meets major global standards for synthetic fiber reinforcement:

-

ASTM C1116 / C1116M – Standard Specification for Fiber-Reinforced Concrete

-

EN 14889-2:2006 – Synthetic Fibers for Concrete, Class Ia

Typical Applications of Polyester Fiber Reinforcement

Concrete & Infrastructure

-

Concrete slabs, industrial floors, pavements

-

Precast concrete panels, elements & factory production

-

Bridge decks, highways, airport runways

Waterproofing & Durability

-

Basements, tunnels, tanks, pools

-

Crack-resistant waterproof concrete

Shotcrete & Repair

-

Tunnel linings, slopes, underground structures

-

Repair mortars, overlays, resurfacing

Mortars & Dry-Mix Materials

-

Plastering mortar, tile adhesives, decorative concrete

-

Specialty dry-mix mortars needing micro reinforcement

Hong Kong-Zhuhai-Macao Bridge

Da Nang Pier, Vietnam

Hangzhou Olympic Center

Usage Guidelines for Optimal Performance

Learn how to use PIONEER® HPM® PET fibers effectively for consistent fiber reinforcement in concrete and mortars.

-

Compatible with standard fiber-reinforced concrete and mortar mix designs.

-

Typical dosage of 0.9 kg/m³; adjustable from 0.6 to 1.8 kg/m³ depending on project demands.

-

Recommended fiber length: 6–12 mm for mortars and plasters; 12–19 mm for concrete reinforcement.

-

Add fibers during batching with cement and aggregates, extending mixing time to ensure uniform dispersion and prevent fiber clumping.

-

Follow standard placing and curing practices; fibers act as complementary reinforcement and do not replace structural steel.

Custom Fiber Solutions for Concrete & Mortar

Tailored fiber lengths, blends, and packaging designed to meet your specific fiber-reinforced concrete and mortar reinforcement needs.

Lengths:

-

Various lengths are available to fit specific application requirements.

Packaging:

-

Bulk packaging in ton bags for large projects.

-

Small packs in plastic or water-soluble bags for easy dosing and handling.

-

OEM/ODM services for distributors and private-label projects worldwide.

Learn more about Micro Synthetic Fibers

-

HPM® PP - Monofilament Micro Fiber

-

HPM® PP Mesh - Fibrillated Mesh Fiber

-

HPM® UF PP - Ultra-Fine Polypropylene

-

HPM® SD PP - Self-Dispersing PP Fiber

-

HPM® AR - Alkali-resistant Glassfiber

-

HPM® PET - Polyester Micro Fiber

Why Choose PIONEER® as Your Concrete Fiber Supplier

Partner with a direct manufacturer with over 22 years of expertise in synthetic fiber reinforcement for concrete and mortar.

22 Years of Expertise in Fiber Reinforcement

PIONEER® provides consistent, high-performance fibers that ensure long-term success in concrete slabs, precast elements, industrial floors, and critical infrastructure projects, making us a trusted supplier in the global market.

1,000+ Projects in 20+ Countries

Our fibers are applied in major projects, including the Hong Kong-Zhuhai-Macao Bridge, Bangladesh Subsea Tunnel, Walmart Superstores, and metro systems, demonstrating our proven capability in fiber-reinforced concrete and mortar applications.

Direct Manufacturer, One-Stop Service

We provide complete technical support, including dosage optimization, mix design consultation, and on-site application guidance to ensure your projects succeed with fiber-reinforced concrete and mortar.

PIONEER® Headquarters

26,500m² production base

Advanced fiber dispersibility

Exceptional tensile strength

Explore Our Full Concrete Fiber Solutions >>

FAQ

Polyester fiber has a higher modulus and better crack-bridging capability compared to polypropylene fibers, and unlike steel fibers, it does not corrode or require special mixing equipment. Its balanced strength, stability, and chemical resistance make it ideal for micro-reinforcement across various concrete applications.

Polyester fiber disperses uniformly throughout the mix, creating a three-dimensional reinforcement network that controls plastic shrinkage, reduces drying shrinkage, and prevents microcracks from spreading. This significantly improves concrete integrity during early-age curing.

Yes. By reducing cracking, improving tensile strength, enhancing freeze–thaw resistance, and minimizing surface defects, polyester fibers extend the long-term durability of concrete. This results in longer service life for pavements, floors, precast elements, and repair systems.

Absolutely. Polyester fiber does not rust, discolor, or leave visible residue on the surface, making it ideal for decorative, architectural, and exposed concrete finishes. It improves surface quality while maintaining aesthetics.

No special equipment is required. Polyester fibers can be added directly into standard concrete mixers and batch plants. They disperse easily without clumping, making them fully compatible with conventional mixing, pouring, and finishing processes.

Explore More Concrete Fibers :

Explore More PIONEER Products :

Why Choose Us?

Proven Expertise & Greater Savings

22 years of focus

on fiber reinforcement solutions.

5,000 tons yearly

from advanced manufacturing.

20+ countries served

with global product distribution.

1,000 projects proven

in diverse applications worldwide.

Looking for a Quote or More Information about Our Fibers?

At PIONEER, we’re committed to delivering the best and most relevant information to support your needs. Reach out to us for more details and discover the benefits we offer:

-

Factory-Direct Pricing

-

Expert Guidance on Fiber Applications

-

Customized Solutions for Your Project

-

Fiber Samples Available for Testing

Privacy Assurance: We respect your privacy and will never share your information.

Contact Us

For product inquiries, OEM/ODM partnerships, or becoming a distributor: Sales@pioneerfibre.com

For technical support and application guidance: Support@pioneerfibre.com

Regional WhatsApp Support

We typically respond within 24 hours, ensuring your project continues without delays.

-

Americas: +1 (702) 307-8327

-

Europe: +86 151 6240 5106

-

Middle East & Africa:+1 (949) 317-7180

-

Asia-Pacific:+86 190 1543 5408